In recent years, the global energy landscape has been undergoing a significant transition, driven by the urgent need to combat climate change and reduce greenhouse gas emissions. At the forefront of this transition is hydrogen, often referred to as the “fuel of the future,” due to its potential to decarbonize key sectors such as transportation, industry, and power generation. Among the various methods of hydrogen production, Proton Exchange Membrane (PEM) electrolysis has emerged as a promising technology due to its efficiency, scalability, and ability to produce green hydrogen when powered by renewable energy sources. As we approach 2025, the development of PEM hydrogen production is poised to play a critical role in shaping a sustainable energy future. This article explores the growth prospects, technological advancements, challenges, and market dynamics of PEM hydrogen production by 2025.

The Rise of PEM Electrolysis Technology

PEM electrolysis is a process that uses a solid polymer electrolyte as the medium for conducting protons from the anode to the cathode during water splitting. This technology offers several advantages over traditional alkaline electrolysis, including higher efficiency, faster response times, and greater compatibility with intermittent renewable energy sources like wind and solar power. Furthermore, PEM electrolyzers are compact and modular, making them well-suited for decentralized hydrogen production.

As of 2023, the global hydrogen market has witnessed substantial investment in PEM technology, driven by government policies, private sector initiatives, and international commitments to achieve net-zero emissions. Countries such as Germany, Japan, South Korea, and the United States have announced ambitious hydrogen strategies that prioritize the deployment of PEM electrolyzers. For instance, the European Union’s “Green Deal” and “Hydrogen Strategy” aim to install at least 40 gigawatts (GW) of electrolyzer capacity by 2030, with a significant share expected to come from PEM systems.

Market Dynamics and Growth Prospects

The market for PEM electrolysis is expected to grow exponentially by 2025, fueled by several key factors:

- Policy Support and Incentives: Governments worldwide are introducing policies and financial incentives to accelerate the adoption of green hydrogen technologies. Subsidies for renewable-powered electrolyzers, carbon pricing mechanisms, and tax credits for clean energy projects are creating a favorable environment for PEM hydrogen production.

- Corporate Commitments: Major corporations in sectors such as energy, automotive, and chemicals are committing to decarbonization goals, which include investments in green hydrogen. Companies like Shell, Siemens Energy, and Toyota are actively developing projects that integrate PEM electrolyzers into their operations.

- Cost Reductions: Technological advancements and economies of scale are driving down the cost of PEM electrolyzers. By 2025, it is anticipated that the cost per kilowatt of PEM systems will decrease significantly, making green hydrogen more competitive with fossil fuel-derived hydrogen (gray hydrogen) and blue hydrogen (produced with carbon capture).

- Renewable Energy Integration: The rapid expansion of renewable energy capacity globally provides a strong foundation for PEM electrolysis. As wind and solar power become more affordable and abundant, they can supply the electricity needed to produce green hydrogen at scale.

- Emerging Applications: The versatility of hydrogen is unlocking new applications across various industries. From fuel cell vehicles to industrial feedstocks and energy storage solutions, the demand for clean hydrogen is expected to grow substantially.

Technological Advancements in PEM Electrolyzers

To meet the growing demand for green hydrogen, significant advancements in PEM electrolysis technology are underway. By 2025, several innovations are expected to enhance the performance and cost-effectiveness of PEM electrolyzers:

- Improved Catalyst Materials: Researchers are developing advanced catalyst materials that reduce the need for expensive platinum-group metals (PGMs) while maintaining high efficiency and durability. Alternatives such as non-precious metal catalysts and composite materials are gaining traction.

- Enhanced Membrane Performance: Innovations in membrane design are improving proton conductivity, reducing degradation rates, and extending the lifespan of PEM electrolyzers. These advancements contribute to lower operational costs and increased reliability.

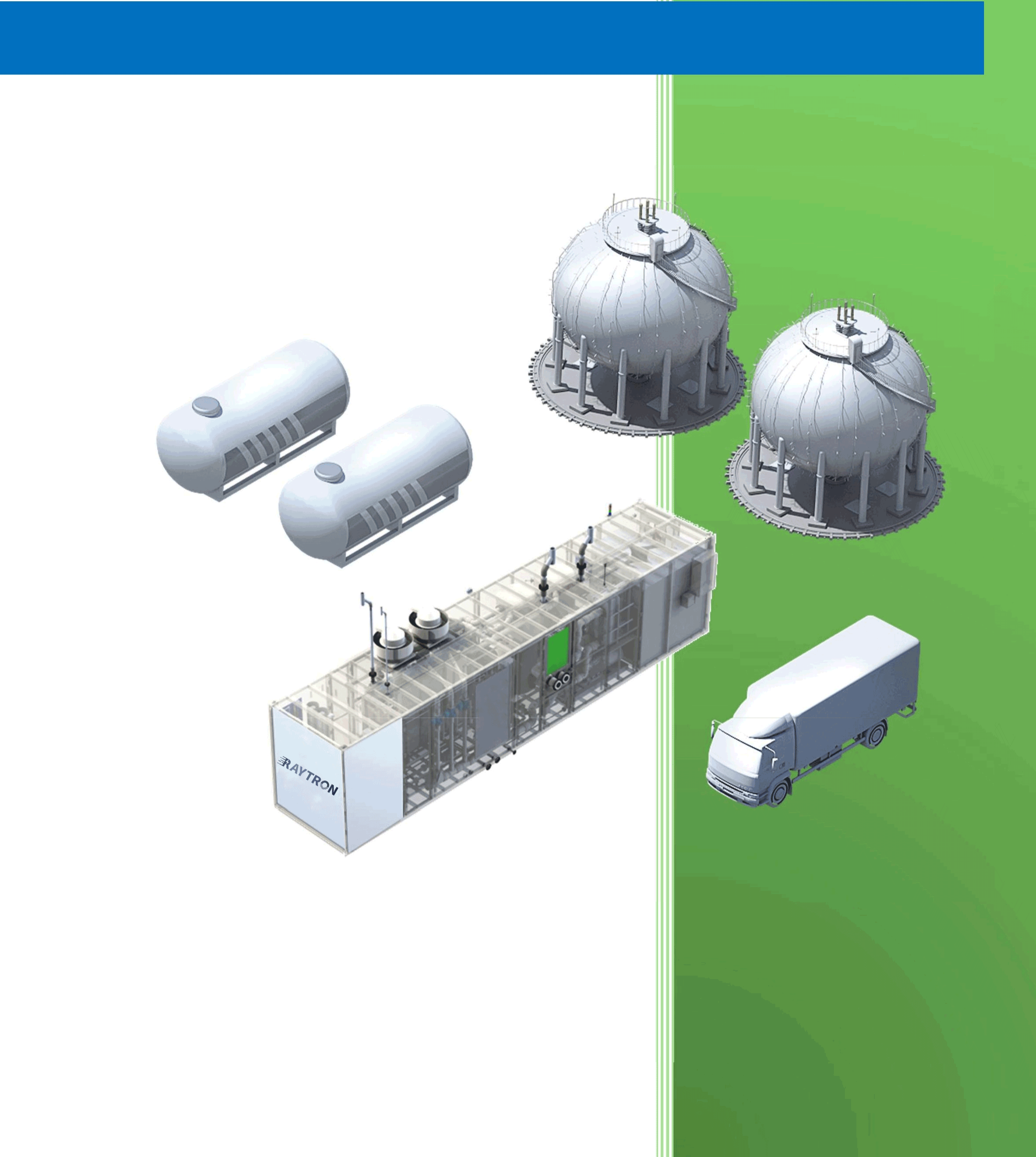

- System Scalability: Manufacturers are focusing on scaling up PEM electrolyzer systems to meet industrial-scale hydrogen production requirements. Modular designs and standardized components are enabling faster deployment and integration into large-scale projects.

- Digital Optimization: The integration of digital technologies such as artificial intelligence (AI) and machine learning is optimizing the operation and maintenance of PEM systems. Predictive analytics and real-time monitoring enhance efficiency and minimize downtime.

Challenges Facing PEM Hydrogen Production

Despite its promising future, PEM hydrogen production faces several challenges that must be addressed to realize its full potential by 2025:

- High Capital Costs: The initial investment required for PEM electrolyzers remains a significant barrier to widespread adoption. While costs are decreasing, further reductions are needed to compete with traditional hydrogen production methods.

- Material Availability: The reliance on scarce and expensive materials such as PGMs poses supply chain risks. Developing alternative materials and recycling strategies will be essential to ensure long-term sustainability.

- Infrastructure Development: The lack of adequate hydrogen infrastructure, including storage facilities, pipelines, and refueling stations, limits the scalability of PEM hydrogen production. Coordinated efforts between governments and industry stakeholders are required to build the necessary infrastructure.

- Renewable Energy Supply: The availability of low-cost renewable electricity is critical for green hydrogen production. Seasonal variability in renewable energy generation can impact the consistency of hydrogen output.

- Regulatory Hurdles: The absence of standardized regulations and certification schemes for green hydrogen creates uncertainty for investors and project developers. Harmonized policies at the international level are needed to facilitate market growth.

The Road Ahead: Opportunities by 2025

As we look toward 2025, several opportunities can accelerate the development of PEM hydrogen production:

- Public-Private Partnerships: Collaboration between governments, research institutions, and private companies can drive innovation and investment in PEM technology. Public funding for research and development (R&D) programs can complement private sector initiatives.

- Global Collaboration: International cooperation on hydrogen standards, trade agreements, and joint projects can create a unified market for green hydrogen. Initiatives such as the Hydrogen Council are fostering dialogue among stakeholders worldwide.

- Sector Coupling: Integrating hydrogen into multiple sectors—such as power generation, transportation, and industry—can create synergies that enhance overall system efficiency. For example, excess renewable electricity can be used to produce hydrogen during periods of low demand.

- Decentralized Production Models: Deploying small-scale PEM electrolyzers in remote or off-grid locations can provide localized solutions for clean energy access while reducing transmission losses.

- Education and Workforce Development: Building a skilled workforce capable of designing, operating, and maintaining PEM systems is essential for scaling up production capabilities.

Conclusion

By 2025, Proton Exchange Membrane (PEM) electrolysis is expected to play a pivotal role in advancing global efforts toward a sustainable energy future. With strong policy support, technological innovations, and growing market demand for green hydrogen, PEM technology has the potential to revolutionize clean energy systems across multiple sectors. However, overcoming challenges such as high costs, material constraints, and infrastructure gaps will require concerted action from governments, industry leaders, and researchers.

As we move closer to 2025, it is crucial to maintain momentum in scaling up PEM electrolysis projects while addressing barriers to adoption. By doing so, we can unlock the full potential of green hydrogen as a cornerstone of the global energy transition—ushering in an era of cleaner air, reduced carbon emissions, and a more resilient energy system for generations to come.