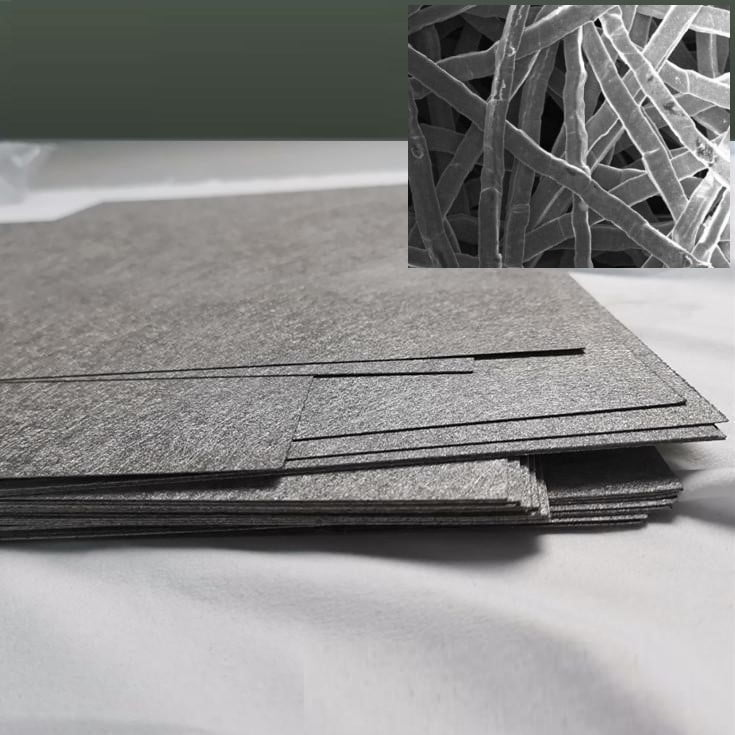

1. Introduction: A Material at the Crossroads of Innovation

Composite titanium felt stands as a testament to the convergence of material science and industrial necessity. Its journey from a corrosion-resistant curiosity to a linchpin of sustainable technology highlights its adaptability. Yet, as industries push toward net-zero targets and Industry 4.0, this material faces both unprecedented opportunities and existential challenges. This article maps the frontier of composite titanium felt research, exploring its potential in space exploration, AI-driven design, and self-healing systems, while dissecting barriers like cost, scalability, and regulatory fragmentation.

2. Emerging Applications: Beyond Terrestrial Limits

2.1 Space Exploration and Extraterrestrial Infrastructure

NASA and ESA are reimagining titanium felt for off-world applications:

- Radiation Shielding:

- Lunar Habitats: Multi-layered titanium felt composites (Ti + polyethylene) block 85% of cosmic rays at 1/3 the weight of aluminum.

- Mars Missions: 2025 trials will test felt-lined suits reducing astronaut radiation exposure by 50%.

- In-Situ Resource Utilization (ISRU):

- Moon-based Electrolyzers: NASA’s Artemis program aims to use lunar regolith-derived titanium felt for oxygen generation, targeting 1 ton/month output by 2030.

2.2 Wearable and Implantable Electronics

Flexible titanium felt hybrids are bridging the gap between durability and biocompatibility:

- Stretchable Batteries:

- Ti felt/polyurethane composites achieve 350% elongation with 95% capacity retention after 10,000 bends (Science Robotics, 2023).

- Applications: Military exoskeletons, medical wearables.

- Neural Interfaces:

- Porous Ti felt electrodes record brain signals with 10x lower impedance than platinum-iridium, enabling precise Parkinson’s treatment (Nature Biomedical Engineering, 2024).

2.3 Quantum and Nuclear Technologies

- Quantum Computing Cooling:

- Ti felt heat sinks with graphene coatings dissipate 500 W/cm² at 4K, critical for superconducting qubits.

- Fusion Reactor First Walls:

- Tungsten-coated titanium felt withstands 10 MW/m² plasma loads in ITER’s 2026 tests.

3. AI-Driven Material Innovation

3.1 Generative Design Algorithms

Machine learning (ML) is collapsing R&D timelines:

- Generative Adversarial Networks (GANs):

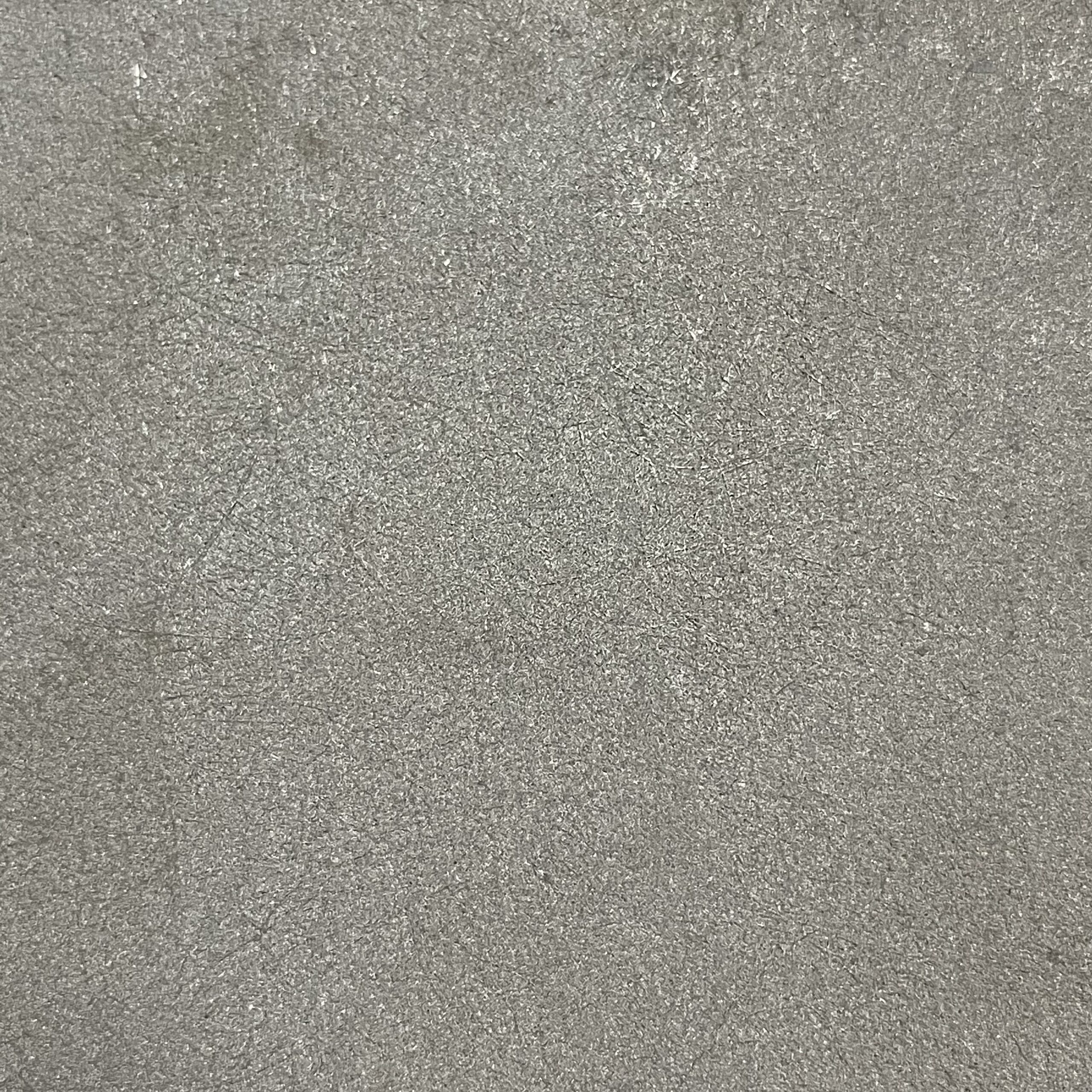

- Trained on 50,000+ SEM images, MIT’s “TitanGAN” designs felt architectures with 22% higher conductivity than human prototypes.

- Multi-Objective Optimization:

- Google DeepMind’s algorithm balances porosity (70%), strength (>100 MPa), and cost (<$500/m²) in 12-hour simulations vs. 6-month lab trials.

3.2 Digital Twins and Process Control

- LPBF 3D Printing Digital Twins:

- Siemens’ software predicts melt pool dynamics in real-time, reducing printing defects by 90%.

- AI-Enhanced CVD:

- Neural networks adjust gas flow rates to deposit uniform 5 nm Pt coatings across 1 m² felt sheets.

4. Multi-Functional Composites: The Next Frontier

4.1 Self-Cleaning and Anti-Fouling Systems

- Photocatalytic TiO₂ Coatings:

- UV-activated TiO₂ decomposes organic pollutants on air filters, achieving 99% PM2.5 removal without manual cleaning.

- Case Study: Tokyo’s 2024 smart buildings use Ti felt facades to cut HVAC energy use by 25%.

4.2 Embedded Sensors and Energy Harvesting

- Piezoelectric Ti Felt:

- ZnO nanowire-integrated felt generates 10 μW/cm² from mechanical vibrations (e.g., wind turbines).

- Strain Mapping:

- Carbon nanotube (CNT) networks embedded in Ti felt detect micro-cracks with 0.1% strain resolution.

4.3 Self-Healing Architectures

- Microcapsule Technology:

- Epoxy-filled capsules rupture under stress, sealing cracks in <1 minute.

- Applications: Satellite antennas, deep-sea oil filters.

5. Cost Reduction Strategies

5.1 Material Alternatives

- Low-Grade Titanium Alloys:

- Ti-3Al-2.5V (Grade 9) offers 30% cost savings over Grade 2 while retaining 85% corrosion resistance.

- Recycled Feedstock:

- Boeing’s 2025 initiative targets 50% recycled Ti in aerospace felt, slashing CO₂ by 40%.

5.2 Manufacturing Breakthroughs

- Binder Jet 3D Printing:

- Desktop Metal’s “ExOne” system prints Ti felt at 150/����.����’�150/kgvs.LPBF’s500/kg.

- Roll-to-Roll Sintering:

- Thyssenkrupp’s continuous line produces 10 m/min felt sheets, 20x faster than batch sintering.

5.3 Energy and Labor Optimization

- Solar-Powered Sintering:

- Heliogen’s concentrated solar furnaces reach 1,300°C with zero emissions, cutting energy costs by 70%.

- Robotic Fiber Alignment:

- Fanuc’s AI-guided robots assemble non-woven mats with 0.01 mm precision, eliminating manual labor.

6. Standardization and Global Collaboration

6.1 Regulatory Frameworks

- ISO/ASTM Standards:

- Draft standard ISO 52907 (2025) defines porosity grades (P50-P90) and tensile strength thresholds (>50 MPa).

- FDA’s 2024 guidance mandates <0.1 ppm Ni leaching in biomedical Ti felt.

6.2 Cross-Industry Consortia

- Hydrogen Council’s Ti-Felt Task Force:

- Members: Toyota, Shell, Sandvik. Goals: Standardize electrolyzer electrodes by 2026.

- EU’s Horizon Europe “Ti4Energy”:

- €200M fund supports 15 projects, including graphene-Ti felt supercapacitors and offshore wind turbine filters.

7. Challenges: The Roadblocks to Ubiquity

7.1 Technical Barriers

- High-Temperature Creep:

- At 800°C, Ti felt loses 30% compressive strength over 1,000 hours due to grain boundary sliding.

- Solution: Dispersion-strengthened Ti-Y₂O₃ alloys (under development at Oak Ridge National Lab).

7.2 Economic Hurdles

- Capital Intensity:

- A full-scale LPBF production line requires $5M+ upfront investment, deterring SMEs.

- Mitigation: Equipment leasing models (e.g., 3D Systems’ “Print-as-a-Service”).

7.3 Knowledge Gaps

- Long-Term Environmental Impact:

- Nanoparticle leaching from Pt-coated felt in marine environments remains unstudied.

- Initiative: EU’s “NanoSafe” 10-year monitoring program launched in 2023.

8. Conclusion: A Call for Ecosystem-Wide Synergy

Composite titanium felt’s destiny hinges on transcending siloed innovation. From AI-optimized lunar habitats to self-healing ocean sensors, its versatility is boundless—yet realizing this potential demands unprecedented collaboration. Academia must deepen fundamental research on nano-titanium interactions; industry must scale low-carbon production; policymakers must harmonize global standards. As the World Economic Forum’s 2024 Advanced Materials Compact underscores, titanium felt isn’t just a material—it’s a microcosm of humanity’s capacity to engineer a sustainable future.