Introduction

Titanium felt microporous composite products are advanced materials. They combine titanium felt with microporous structures. These products are used in various high-performance applications. They offer unique properties like high porosity and strength. This article explores their properties, manufacturing, applications, and future prospects.

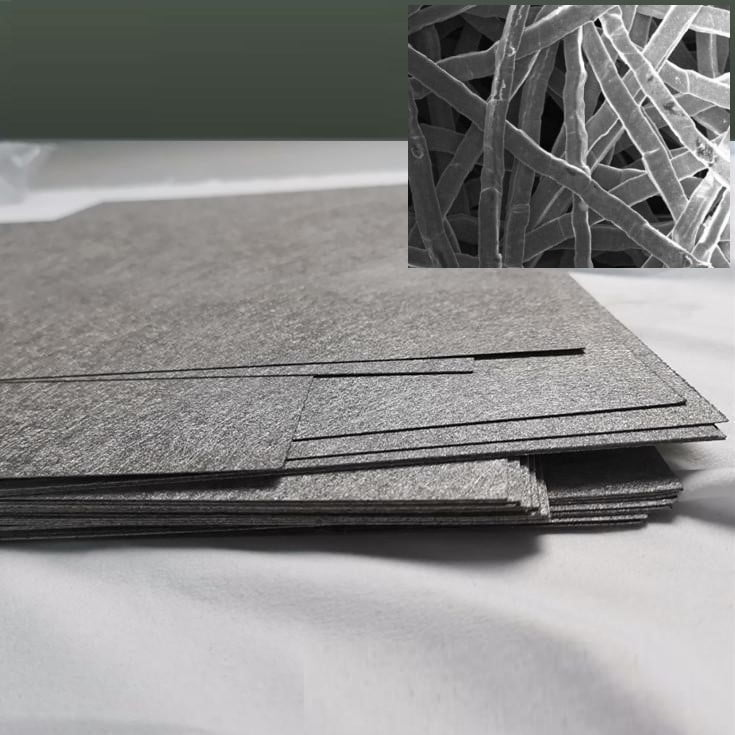

What are Titanium Felt Microporous Composite Products?

Titanium felt microporous composite products are specialized materials. They consist of a titanium felt base. The base is integrated with a microporous layer. This combination enhances the material’s properties. Titanium provides strength and corrosion resistance. The microporous layer adds functionality. These products are used in demanding environments.

Manufacturing Process

The production involves several steps. High-purity titanium fibers are processed first. These fibers are woven into a felt-like structure. The titanium felt is then cleaned thoroughly. A microporous layer is added using techniques like sintering. This creates a composite with enhanced properties. The final product is a durable and functional material.

Properties of Titanium Felt Microporous Composite Products

These products have several key properties. They are highly porous, allowing efficient fluid flow. The materials are mechanically strong and durable. They resist corrosion and high temperatures. Titanium felt microporous composites are also lightweight. They maintain structural integrity under stress. These properties make them ideal for various applications.

Applications in Filtration

Titanium felt microporous composites are widely used in filtration. They serve as filter media in harsh environments. The materials are used in gas and liquid filtration. They effectively remove particulates and contaminants. Their durability ensures long service life. This makes them suitable for industrial applications.

Use in Electrochemical Processes

These composites are used in electrochemical applications. They serve as electrodes in various cells. The materials enhance electron transfer efficiency. They are used in fuel cells and electrolyzers. Titanium felt microporous composites improve performance. This is crucial for energy conversion and storage.

Applications in Chemical Industry

The chemical industry benefits from these composites. They are used in reactors and converters. The materials withstand harsh chemicals and high temperatures. They ensure efficient reaction processes. Titanium felt microporous composites are also used in catalysis. Their properties enhance catalytic efficiency. This is vital for chemical production.

Role in Environmental Protection

These composites are used in environmental applications. They are employed in air and water purification systems. The materials help remove pollutants effectively. They are used in catalytic converters for emission control. Titanium felt microporous composites contribute to cleaner environments. Their use supports sustainable development.

Medical Applications

The medical field utilizes these composites. They are used in implantable medical devices. The materials’ biocompatibility is a key advantage. Titanium felt microporous composites are used in drug delivery systems. They ensure controlled release of medications. Their stability and functionality enhance medical treatments.

Advantages Over Other Materials

Titanium felt microporous composites offer several advantages. They combine the strength of titanium with the functionality of microporous structures. The materials are more durable than traditional filters. They are also more cost-effective in the long run. Titanium felt microporous composites perform better in harsh environments. They are more resistant to corrosion and high temperatures. These advantages make them a preferred choice in many applications.

Challenges and Limitations

Despite their advantages, these composites have some limitations. The cost of production is high. This is due to the complex manufacturing process. The materials are also heavy compared to some alternatives. This can be a drawback in certain applications. Ongoing research aims to address these challenges. Improvements in manufacturing techniques are expected.

Recent Developments

Recent advancements have improved these composites. New manufacturing techniques enhance durability. Researchers are developing thinner microporous layers. This reduces material costs without compromising performance. Advances in titanium fiber processing have also been made. These improvements enhance the material’s properties. The future looks promising for titanium felt microporous composites.

Future Prospects

The demand for these composites is expected to grow. Their applications in filtration and energy are expanding. The materials are crucial for environmental protection. Advances in manufacturing will reduce costs. This will make titanium felt microporous composites more accessible. Their use in various industries will continue to increase. This material has a bright future.

Economic Impact

Titanium felt microporous composites have a significant economic impact. They support industries like energy, chemicals, and healthcare. The materials drive innovation in these sectors. Their production creates jobs and stimulates economic growth. The demand for these composites boosts the titanium market. This has a ripple effect on the global economy. The material’s economic importance cannot be overstated.

Environmental Benefits

These composites offer environmental benefits. They enhance the efficiency of filtration systems. This reduces pollution and improves air and water quality. The materials are used in emission control technologies. They help in reducing greenhouse gas emissions. Titanium felt microporous composites contribute to sustainable development. Their use supports environmental protection efforts.

Comparison with Other Filtration Materials

Titanium felt microporous composites are often compared with other materials. Traditional filter media are cheaper but less durable. Ceramic filters are fragile and less efficient. Titanium felt microporous composites strike a balance. They offer the best of both worlds. This makes them a preferred choice in many applications. Their performance and cost-effectiveness are unmatched.

Case Studies

Several case studies highlight the effectiveness of these composites. In a chemical plant, they improved filtration efficiency by 30%. A fuel cell manufacturer reported longer lifespan with these materials. An environmental project achieved better emission control using these composites. These examples demonstrate their practical benefits. They underscore the material’s importance in various industries.

Conclusion

Titanium felt microporous composite products are versatile and high-performance materials. They combine the strengths of titanium with the functionality of microporous structures. These materials are essential in many advanced applications. Their use in filtration, energy, and healthcare is crucial. Despite some challenges, ongoing research is addressing these issues. The future of titanium felt microporous composites is promising. They will continue to play a vital role in technological advancements.