Hydrogen is a clean and versatile energy carrier with growing global demand. Among the various methods of hydrogen production, Proton Exchange Membrane (PEM) electrolysis has emerged as a promising technology. PEM electrolysis offers several advantages over traditional hydrogen production methods, making it an attractive choice for sustainable energy systems.

1. High Efficiency in Hydrogen Production

PEM electrolysis operates with high efficiency, converting electricity into hydrogen effectively. The process minimizes energy losses, ensuring optimal utilization of input electricity. This high efficiency is particularly beneficial when using renewable energy sources.

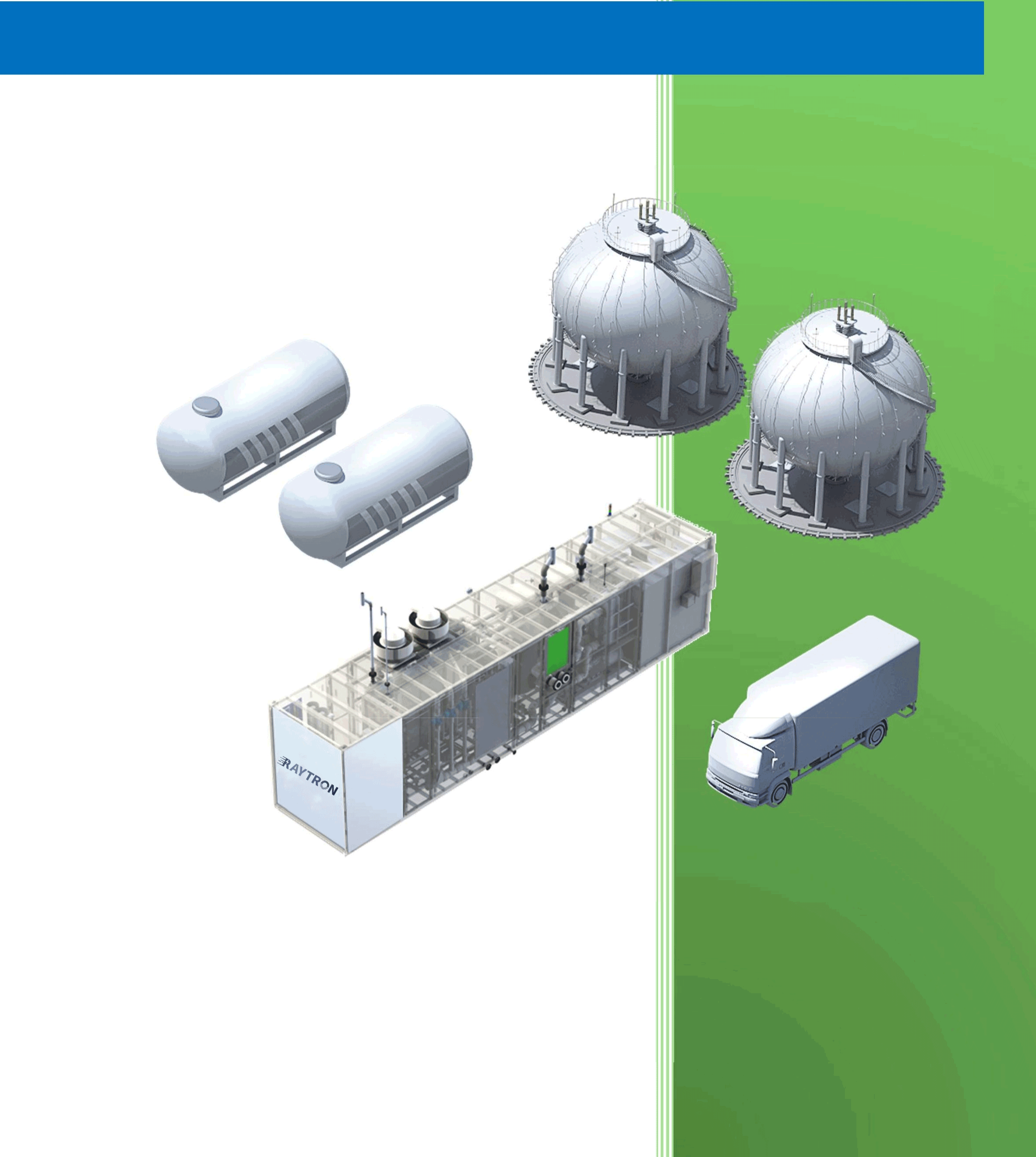

2. Compact and Lightweight Design

PEM electrolyzers are compact and lightweight compared to other systems. Their small footprint makes them suitable for decentralized hydrogen production. This feature is ideal for applications with limited space or mobile energy solutions.

3. Faster Response Time

PEM electrolyzers exhibit rapid start-up and shutdown capabilities. They can quickly adjust to fluctuations in electricity supply or demand. This flexibility makes them compatible with intermittent renewable energy sources like wind and solar power.

4. High Purity Hydrogen Output

PEM electrolysis produces hydrogen with exceptionally high purity levels, often exceeding 99.99%. High-purity hydrogen is essential for applications such as fuel cells and industrial processes. This eliminates the need for additional purification steps, reducing costs.

5. Scalability for Various Applications

PEM electrolyzers are highly scalable, suited for small-scale and large-scale hydrogen production. They can be deployed in residential, industrial, and commercial settings. This scalability supports diverse applications, from powering vehicles to grid energy storage.

6. Low Operating Temperatures

PEM electrolyzers operate at relatively low temperatures, typically between 50°C and 80°C. This reduces thermal stress on system components and enhances durability. Low operating temperatures also improve system safety and reliability.

7. Compatibility with Renewable Energy

PEM electrolysis is well-suited for integration with renewable energy sources. It efficiently converts surplus renewable electricity into hydrogen for storage or later use. This enables a seamless transition to a low-carbon energy system.

8. Minimal Environmental Impact

PEM electrolysis uses water as the primary feedstock, producing only hydrogen and oxygen as byproducts. It eliminates greenhouse gas emissions associated with fossil fuel-based hydrogen production methods. This contributes to global decarbonization efforts.

9. Low Maintenance Requirements

PEM electrolyzers require minimal maintenance due to their simple design and robust materials. They have fewer moving parts compared to alternative systems, reducing wear and tear. This lowers operational costs over the system’s lifetime.

10. Enhanced Safety Features

PEM electrolyzers incorporate advanced safety features to prevent accidents during operation. Their design minimizes the risk of leaks or hazardous reactions. These safety measures ensure reliable operation in diverse environments.

11. Energy Storage Potential

Hydrogen produced via PEM electrolysis serves as an efficient energy storage medium. It can store excess renewable energy for use during periods of low generation. This capability addresses the intermittency challenges of renewable energy sources.

12. Support for Decentralized Energy Systems

PEM electrolysis enables localized hydrogen production, reducing reliance on centralized facilities. Decentralized systems enhance energy security and reduce transportation costs. They also support remote or off-grid communities in accessing clean energy.

13. Long Operational Lifespan

Advancements in PEM electrolyzer technology have extended their operational lifespan significantly. Durable materials and improved designs ensure reliable performance over time. A longer lifespan translates to better return on investment for users.

14. Potential for Grid Stabilization

PEM electrolyzers can help stabilize electricity grids by absorbing excess power during peak generation periods. They convert surplus electricity into hydrogen, preventing grid overloads. This function supports efficient grid management and reduces waste.

15. Alignment with Hydrogen Economy Goals

PEM electrolysis aligns with global efforts to establish a hydrogen-based economy. It supports large-scale deployment of hydrogen as a clean energy carrier. This contributes to achieving climate goals and reducing dependence on fossil fuels.

16. Support for Emerging Technologies

PEM electrolysis complements emerging technologies such as fuel cells and hydrogen-powered vehicles. It provides a reliable source of high-purity hydrogen for these applications. This integration accelerates the adoption of innovative energy solutions.

17. Reduced Water Consumption

PEM electrolyzers require relatively small amounts of water compared to other hydrogen production methods. Efficient water usage makes them environmentally sustainable in regions facing water scarcity challenges.

18. Continuous Technological Advancements

Ongoing research and development efforts are driving improvements in PEM electrolysis technology. Innovations aim to reduce costs, enhance efficiency, and increase durability further. These advancements make PEM electrolysis increasingly competitive in the market.

19. Economic Opportunities

The adoption of PEM electrolysis creates economic opportunities across the hydrogen value chain. It supports job creation in manufacturing, installation, and maintenance sectors. Additionally, it fosters innovation in related industries.

20. Contribution to Circular Economy

PEM electrolysis promotes a circular economy by utilizing renewable resources like water and electricity sustainably. It minimizes waste generation while producing valuable outputs like hydrogen and oxygen.

In conclusion, Proton Exchange Membrane (PEM) electrolysis offers numerous advantages that position it as a key technology for sustainable hydrogen production. Its high efficiency, scalability, and compatibility with renewable energy make it a cornerstone of future energy systems. By addressing environmental challenges and supporting clean energy transitions, PEM electrolysis plays a vital role in shaping a greener, more sustainable world.