Introduction

Membrane Electrode Assemblies (MEAs) are crucial in fuel cell technology. They convert chemical energy into electrical energy. MEAs are essential for efficient fuel cell operation. This article explores the components, functions, and advancements of MEAs.

Components of Membrane Electrode Assemblies

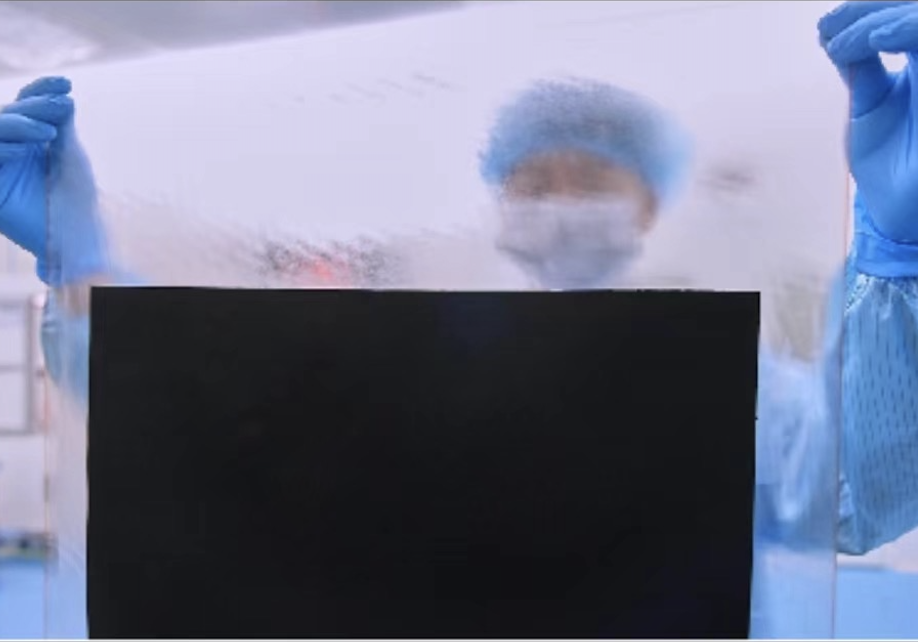

MEAs consist of several key components. These include the proton exchange membrane, electrodes, and catalyst layers. Each component plays a vital role in fuel cell performance.

Proton Exchange Membrane

The proton exchange membrane is central to MEA function. It conducts protons from the anode to the cathode. This membrane is typically made of a polymer material. Nafion is a common choice due to its high proton conductivity.

Electrodes

Electrodes are critical for facilitating reactions. They are composed of porous materials. These materials allow gas diffusion and electron conduction. The anode and cathode are the two electrodes in an MEA.

Catalyst Layers

Catalyst layers are applied to the electrodes. They accelerate the electrochemical reactions. Platinum is often used as a catalyst due to its effectiveness. The catalyst layer must be finely dispersed for optimal performance.

Functioning of Membrane Electrode Assemblies

MEAs enable the conversion of hydrogen and oxygen into water. This process generates electricity and heat. At the anode, hydrogen molecules split into protons and electrons. The protons pass through the membrane to reach the cathode.

Simultaneously, electrons travel through an external circuit. This movement generates electric current. At the cathode, oxygen molecules combine with protons and electrons. This reaction produces water as a byproduct.

Factors Affecting MEA Performance

Several factors influence MEA performance. These include membrane thickness, catalyst loading, and operating conditions. Thinner membranes generally offer lower resistance. However, they may compromise mechanical stability.

Catalyst loading impacts reaction rates. Higher loading can enhance performance but increases cost. Operating conditions such as temperature and humidity also affect efficiency.

Advancements in Membrane Electrode Assemblies

Recent advancements aim to improve MEA efficiency and durability. Researchers are exploring alternative materials for membranes and catalysts.

Alternative Membrane Materials

New membrane materials are being developed for better performance. These materials aim to offer higher conductivity and stability. Sulfonated aromatic polymers are one promising class of materials.

Non-Platinum Catalysts

The high cost of platinum has driven research into alternatives. Non-platinum catalysts are being explored for cost reduction. Transition metal alloys show potential as effective catalysts.

Durability Enhancements

Improving MEA durability is a key research focus. Advanced coatings and reinforcements can enhance lifespan. These innovations aim to reduce degradation under operating conditions.

Applications of Membrane Electrode Assemblies

MEAs have diverse applications in various industries. They are integral to hydrogen fuel cells used in transportation. Fuel cells power vehicles with zero emissions.

Stationary power generation also benefits from MEAs. They provide clean energy solutions for residential and commercial use. Portable electronic devices can also utilize small-scale fuel cells.

Challenges and Future Directions

Despite advancements, challenges remain in MEA development. Cost reduction is a significant hurdle for widespread adoption. Scalability of new materials needs further exploration.

Future research will likely focus on enhancing performance and reducing costs. Collaborations between academia and industry will drive innovation.

Conclusion

Membrane Electrode Assemblies are vital to fuel cell technology. They enable efficient energy conversion with minimal emissions. Ongoing research continues to push the boundaries of MEA capabilities.

Understanding the intricacies of MEAs can lead to better applications. As technology advances, MEAs will play an increasingly important role in sustainable energy solutions.