Hydrogen energy, also known as hydrogen power, is a clean and sustainable energy source that has gained increasing attention in recent years. It has several advantages that make it an attractive option for addressing the world’s energy needs.

Firstly, one of the key benefits of hydrogen energy is its environmental friendliness. When burned, hydrogen only produces water as a byproduct, making it a clean and emission-free fuel. This is in stark contrast to fossil fuels, which release harmful pollutants and greenhouse gases into the atmosphere, contributing to air pollution and climate change.

In addition to being clean, hydrogen energy is also abundant. Hydrogen is the most abundant element in the universe, and it can be produced from a variety of sources, including water, biomass, and natural gas. This means that there is a virtually limitless supply of hydrogen available, making it a reliable and sustainable energy source for the future.

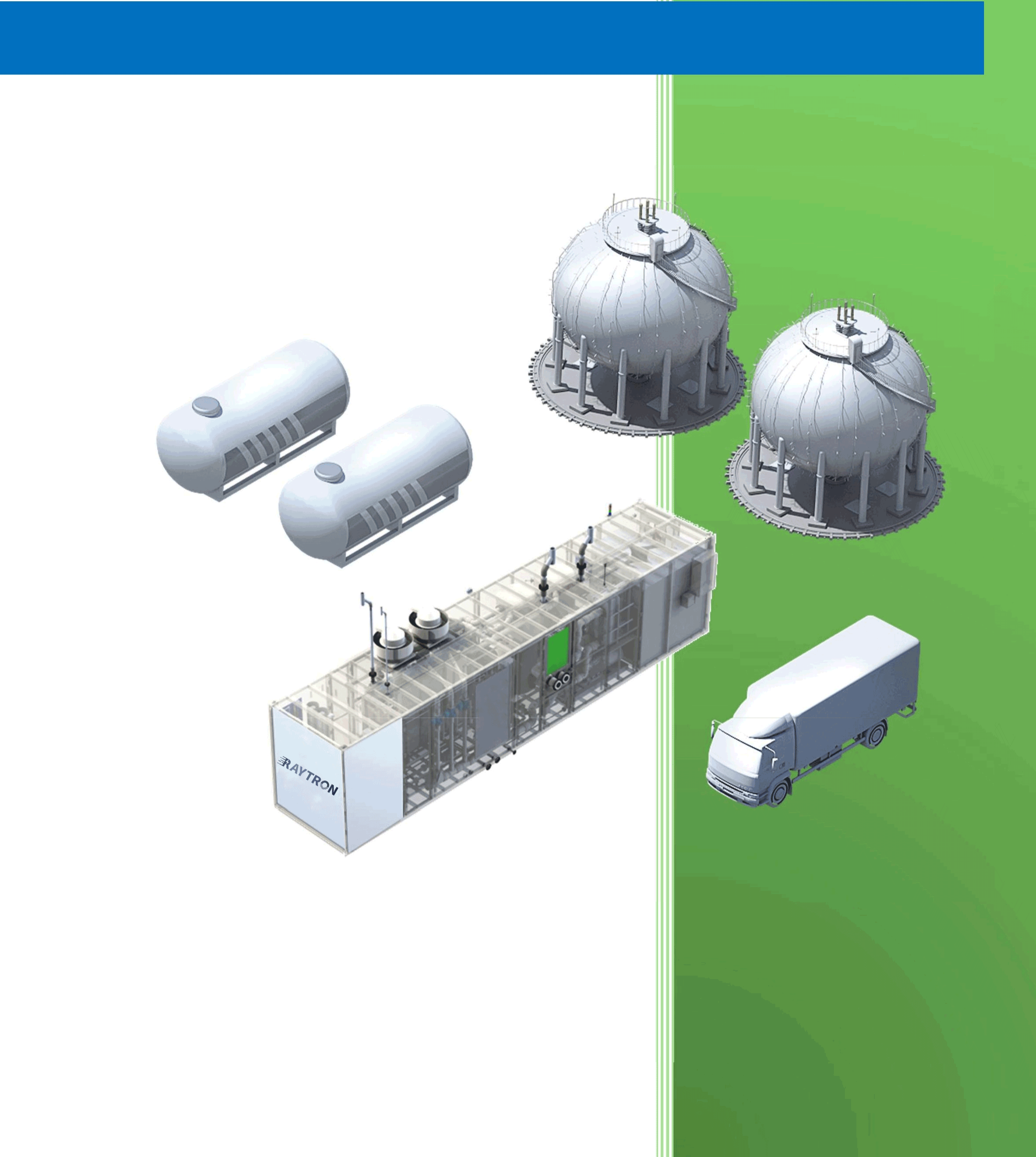

Furthermore, hydrogen energy is versatile and can be used in a wide range of applications. It can be used to power vehicles, generate electricity, and heat buildings, among other uses. This versatility makes it a flexible and adaptable energy source that can meet a variety of energy needs.

Another advantage of hydrogen energy is its potential for energy storage. Unlike other renewable energy sources like solar and wind power, which are intermittent and dependent on weather conditions, hydrogen can be stored and used as needed. This makes it an ideal complement to other renewable energy sources, helping to address the challenge of energy storage and grid stability.

Moreover, hydrogen energy has the potential to create economic opportunities and drive innovation. As the demand for clean energy grows, there will be increasing opportunities for investment and job creation in the hydrogen industry. Additionally, research and development in hydrogen technology could lead to new advancements and breakthroughs in the energy sector.

In conclusion, hydrogen energy offers numerous advantages that make it a promising solution for the world’s energy needs. Its environmental friendliness, abundance, versatility, potential for energy storage, and economic opportunities make it an attractive option for a sustainable energy future. With continued investment and support, hydrogen energy has the potential to play a significant role in addressing global energy challenges and transitioning to a cleaner and more sustainable energy system.