Proton Exchange Membrane (PEM) hydrogen production is an innovative and growing technology. It plays a crucial role in the global energy transition. This method utilizes water electrolysis to produce hydrogen gas. A PEM electrolyzer uses electricity to split water into hydrogen and oxygen. The process is clean and produces no harmful emissions. Its environmental benefits have gained attention in recent years.

Hydrogen is a versatile energy carrier with many applications. It can be used in fuel cells, industrial processes, and transportation. However, traditional hydrogen production methods rely on fossil fuels. These methods, such as steam methane reforming, emit significant carbon dioxide. PEM electrolysis offers a sustainable alternative to these conventional techniques.

One major advantage of PEM hydrogen production is its potential to reduce greenhouse gas emissions. When powered by renewable energy, the process is entirely green. Solar, wind, or hydroelectric power can supply the electricity needed for electrolysis. This eliminates the carbon footprint associated with fossil fuel-based hydrogen production.

The adoption of PEM hydrogen production can also decrease air pollution. Traditional hydrogen production emits pollutants like carbon monoxide and nitrogen oxides. These pollutants contribute to smog and respiratory issues in urban areas. PEM electrolysis avoids these emissions, improving air quality.

Another environmental benefit is the efficient use of water resources. PEM electrolyzers require relatively small amounts of water compared to other industrial processes. Additionally, they do not produce harmful byproducts that could contaminate water supplies. This makes PEM hydrogen production a safer option for ecosystems.

PEM hydrogen production also supports the integration of renewable energy into the grid. Renewable energy sources often face challenges with intermittency. Surplus energy from solar or wind farms can be used for hydrogen production. This stored hydrogen can later be converted back into electricity when needed. It provides a solution for balancing supply and demand in renewable energy systems.

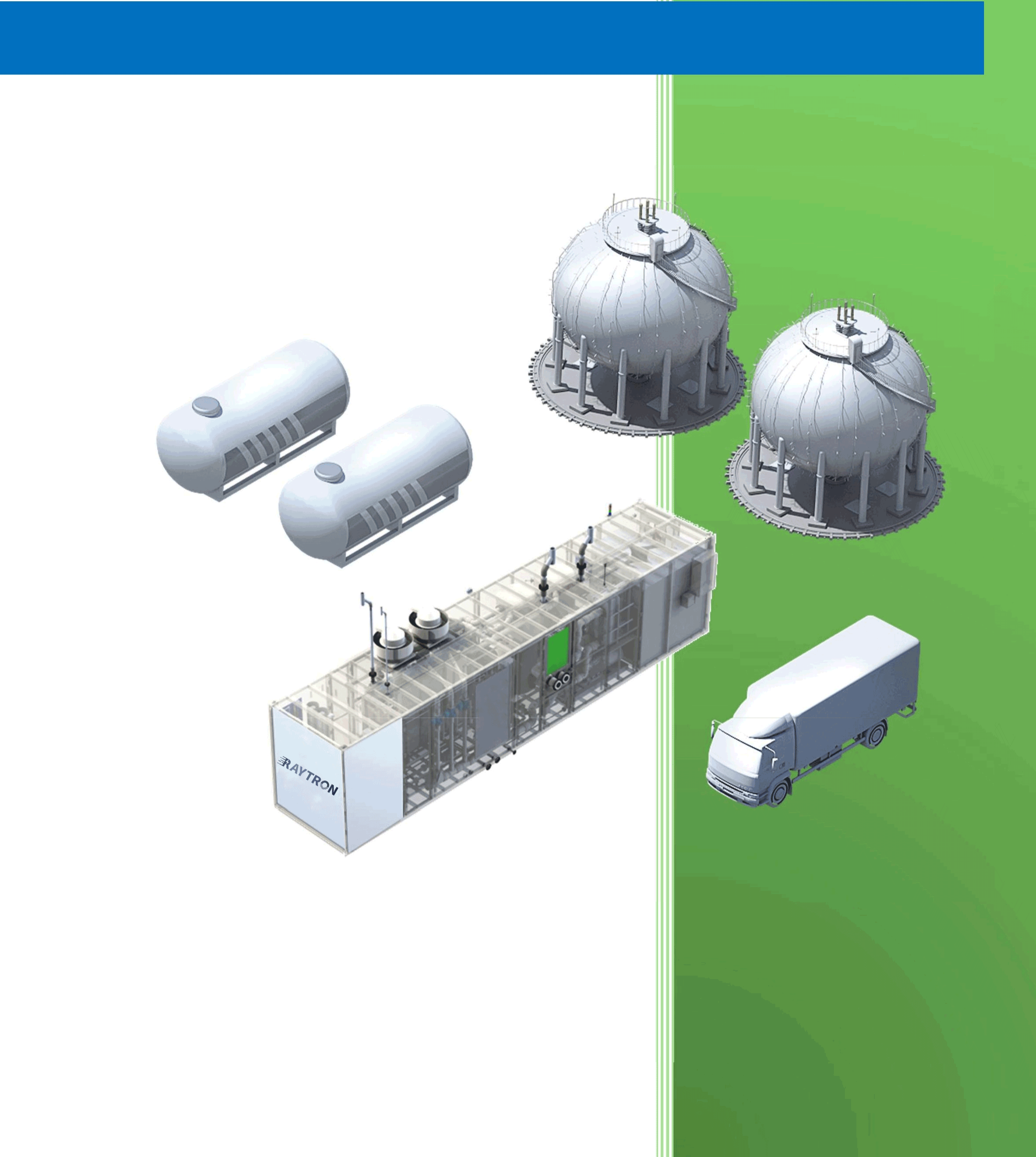

The scalability of PEM electrolyzers is another advantage for environmental sustainability. They can be deployed in small-scale or large-scale applications depending on energy needs. This flexibility makes them suitable for various industries and regions. It also enables localized hydrogen production, reducing transportation emissions.

In addition to environmental benefits, PEM hydrogen production has economic advantages. It creates opportunities for green jobs in manufacturing and maintenance. Governments and industries are investing in hydrogen infrastructure development. These efforts align with global goals for sustainable development and climate action.

Despite its benefits, PEM hydrogen production faces challenges that must be addressed. The high cost of electrolyzers and renewable electricity is a significant barrier. Research and development are needed to improve efficiency and reduce costs. Advances in catalyst materials and system design could enhance performance.

Another challenge is the availability of renewable energy for large-scale hydrogen production. Expanding renewable energy capacity is essential to maximize the environmental benefits of PEM electrolysis. Policymakers must prioritize investments in clean energy infrastructure.

Public awareness and acceptance of hydrogen as an energy carrier are also critical. Educational campaigns can inform communities about the environmental advantages of hydrogen technologies. Collaboration between governments, industries, and academia is essential for widespread adoption.

Safety concerns related to hydrogen storage and transport must also be addressed. Hydrogen is a flammable gas that requires careful handling and infrastructure. Developing robust safety standards and technologies will ensure its safe use.

In conclusion, PEM hydrogen production offers significant environmental benefits. It reduces greenhouse gas emissions, improves air quality, and supports renewable energy integration. Its scalability and efficiency make it a promising solution for sustainable development. Addressing challenges like cost, infrastructure, and safety will unlock its full potential. With continued innovation and investment, PEM hydrogen production can play a key role in a cleaner future.